|

KUNSHAN EMF INDUSTRIAL CO., LTD.

|

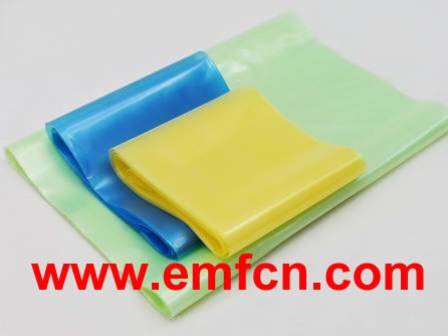

VCI film

| Payment Terms: | T/T,L/C |

| Place of Origin: | , China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

It's used as packaging material for metal parts for anti-rust purpose typically during sea transportation.

VCI Antirust film (Typically for sea transported metal parts)

VCI film series products are produced by combining modern film technology and gas phase antirust (VCI) technology, and by blending, co-extrusion and blow molding of PE resin and VCI with special technology.

It's used as packaging material for metal parts for anti-rust purpose typically during sea transportation.

The products are in accordance with the American Military Standard MIL-PRF-22019D. They have characteristics of transparent and intuitive, good diaphragming performance, long antirust period and easy operation, and are new antirust packaging materials that are economic and of environmental protection.

a) Specification and variety of products:

Appearance :Transparent film / various colors can be made

Patten: Double-layer co-extrusion polyethylene antirust film

Thickness: 0.035mm~0.300mm

Antirust period More than 3 years

b) Product features:

i. It has excellent gas phase and contact antirust performance, with more than 2 years of antirust period;

ii. They are transparent and attractive; and it is easy to observe directly the state of the packaged articles;

iii. Clean and safe to use, and can be recovered completely;

iv. Strong sealing performance and good printing performance;

v. Easy to use, and can be used directly after seal removing;

vi. Have certain waterproof and moisture-proof performance;

vii. They have obvious antirust effect and have overcome the disadvantage of traditional method's insufficient protection to the products. They are especially suitable for antirust packaging in metal parts processing, storage and transportation in trades such as military industry, machinery, automobile fittings, electrician, and hardware, etc.;

viii. Save labor, save time, save the cost, and have prominent comprehensive economic benefits.

c) Applicable field:

i. Spare parts of car and motorcycle.

ii. Mechanical spare parts, medical machinery, precision instrument, cast iron pieces and aviation parts;

iii. Various hardware and powder metallurgy;

iv. Various electric tools, measuring tools and cutting tools;

v. Various bearing, clutch, motor and valve;

vi. Carbon steel, alloy steel, cast iron, steel phosphatization, steel nitridation, steel flange, powder metallurgy, orientation silicon steel, and non-orientation silicon steel, etc.

d) Packaging and storage:

i. The products forms are divided into flat bag, stereoscopic bag, intercalation bag, tubular material and sheet material, etc. They are generally packaged in paper boxs, and can also be packaged in other forms according to user's requirement.

ii. Product should be stored in a dry and cool place and sealed, avoiding original packages damaged;

iii. The storage period of the product is one year since date of production.

e) Operation method:

i. Artificial or machine enwinding enable that the protected metal products will be parceled completely to prevent water and gas entering;

ii. Use volatile corrosion inhibiting materials correctly according to regulations of GB/T 14188

iii. Guarantee cleanness and dryness of the metal material packaged;

iv. Place the surface that contains corrosion inhibitor towards the mental package;

v. Guarantee the relative sealing performance after packaging.